Use Versatile AXYZ CNC Routers for Foam Applications

AXYZ offers solutions for foam processing applications in all shapes and sizes, from one-off custom products to high-volume production. Take advantage of both routing and knife cutting capabilities on the same machine for versatility and reliability.

CHOOSE THE RIGHT CUTTING TOOL

Foam material comes in all types of densities and sizes, so it’s important to know which cutting tool to use to get the precision cut you need.

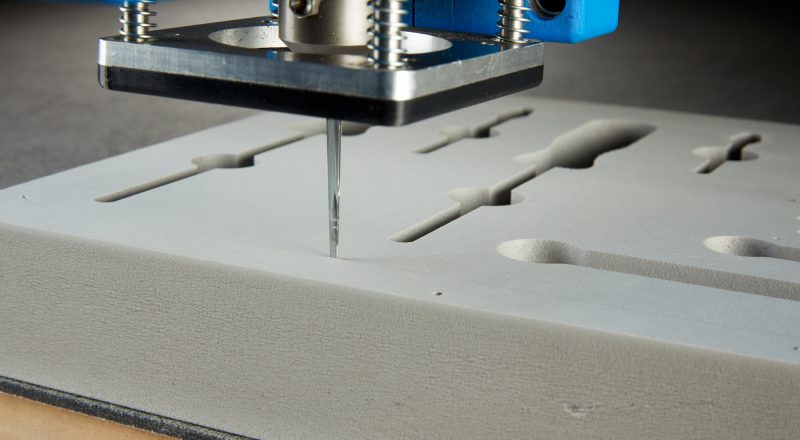

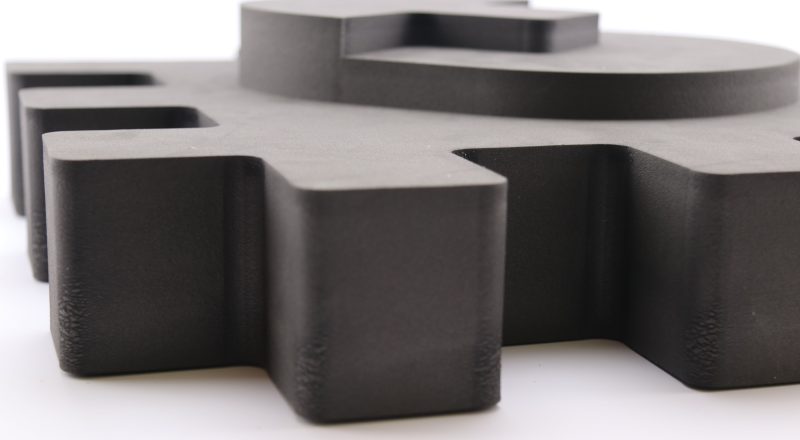

Hard, high-density foams like Polyurethane (PU) will get a nice clean edge finish with a straight flute bit.

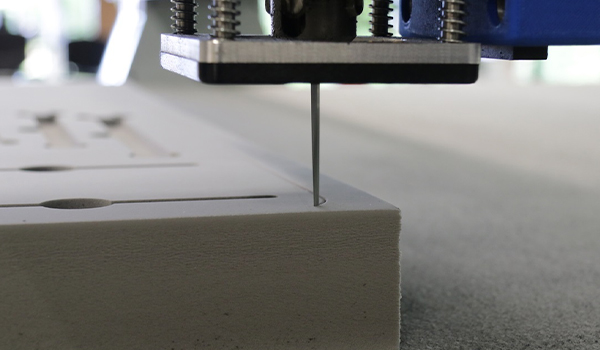

Light, cushy type foams like Polyethylene (PE) require specific oscillating knives for high quality, precision cuts.

5 Benefits of Using a CNC Router for Foam Processing:

✔ Clean Edge Cuts

✔ Pocket Milling

✔ Fast Cutting Capabilities

✔ Multipurpose Capabilities

✔ High Gantry Clearances